Potential Opportunities in the Space Carbon Fiber Composites Market

Valuation Could Climb to $571.9 Million by 2030

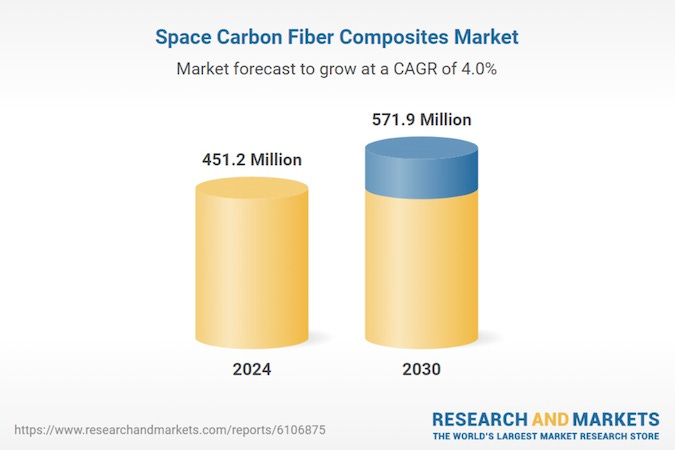

The global market for Space Carbon Fiber Composites was estimated at $451.2 million in 2024 and is projected to reach $571.9 million by 2030, growing at a CAGR of 4.0% from 2024 to 2030, according to a new report from Global Industry Analysts, Inc.

The growth in the global space carbon fiber composites market is driven by several factors including increa…