Partnership Aims to Advance Additive Manufacturing for Space Propulsion

Strategic Alliance Formed Between Vaya Space and Velo3D

A $4 million, two-year Master Services Agreement (MSA) has been formalized between Vaya Space and Velo3D to collaborate on high-performance additive manufacturing R&D and production.

“Additive manufacturing plays a central role in our ability to reduce design complexity, increase performance, and scale production.”

Aaron Blankenship, Vaya Space.

Vaya Space selected Velo3D as a key strategic partner in its propulsion development roadmap. Through the agreement, Vaya Space will leverage https://velo3d.com/’s Rapid Production Solution (RPS) to accelerate production of critical propulsion system components and meet key development timelines. Utilizing Velo3D’s Sapphire printer platform, Vaya Space will print parts in both GRCop42—a NASA-developed copper alloy for high-heat transfer and strength—and Inconel 718, a nickel superalloy known for strength and thermal resilience in aerospace applications. Vaya currently uses the Sapphire platform to produce the world’s first expander cycle hybrid rocket engine; under the agreement, the two companies will work together to optimize Sapphire’s printing parameters, increasing part quality and reducing unit cost and production time.

As part of the partnership, Velo3D will serve as Vaya Space’s exclusive provider of GRCop42 additive components, delivering guaranteed capacity, advanced engineering support, and Flow software training to streamline design-to-production cycles for propulsion assemblies including nozzles, injectors, and turbopumps. The two companies will work collaboratively to produce high-quality engine components for aerospace and defense applications faster and at a lower cost than traditionally achievable. The combination of Velo's closed loop in-situ monitoring with Vaya's fuel grain and tank manufacturing processes will enable full hybrid rocket engines to be produced in days, with the ability to adjust designs and tailor performance profiles to meet the demands of any mission profile.

“Additive manufacturing plays a central role in our ability to reduce design complexity, increase performance, and scale production,” said Aaron Blankenship, VP of Operations at Vaya Space. “Velo3D offers the production readiness, material capabilities, and deep technical partnership we need to bring our vision to life and deliver flight-ready engines on schedule.”

“This partnership is a powerful example of how our Rapid Production Solution helps scale complex hardware manufacturing for today’s most ambitious aerospace companies,” said Dr. Arun Jeldi, CEO of Velo3D. “By combining our capabilities in GRCop42 and Inconel 718 with deep engineering collaboration, we’re helping Vaya Space achieve faster, more cost-effective production—right here in the United States.”

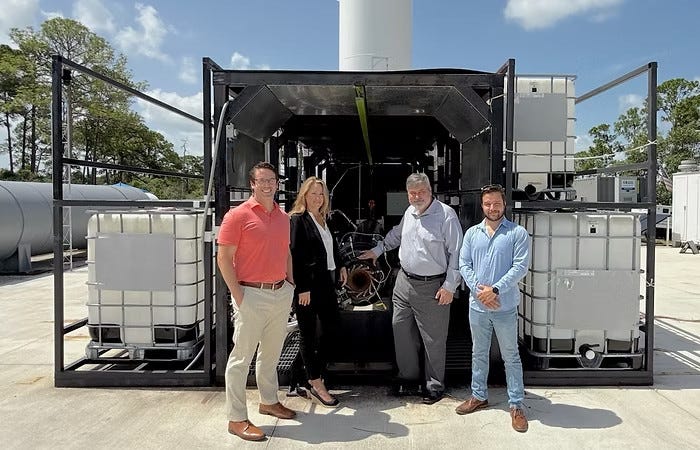

The agreement includes a joint marketing roadmap and formal signing event at Vaya Space’s testing facility in Cocoa, Florida, where one of the propulsion systems produced with Velo3D parts will be on display.