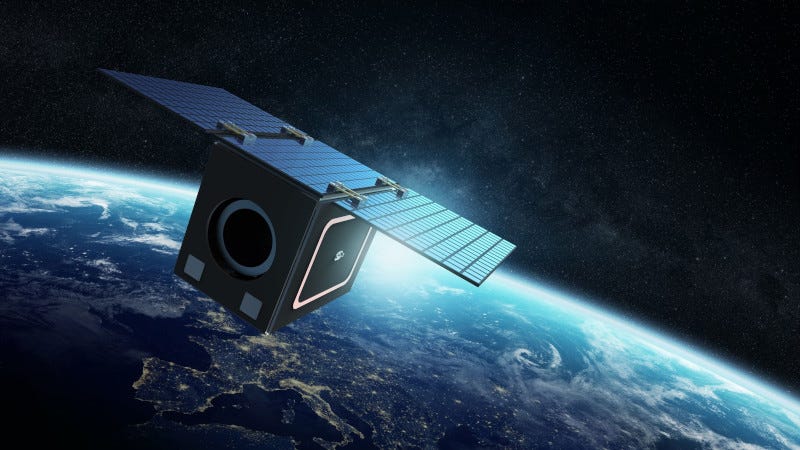

New 3D Printing Method Cuts Solar Array Production Time

Boeing Innovation Speeds Satellite Manufacturing, Reduces Delays

By compressing composite build times by up to six months, Boeing’s new 3D-printed solar array substrate marks a major change in how quickly solar array wings can be produced, the company announced last week. This approach represents a production improvement of up to 50 percent compared to previous process cycles, setting a new standard in satellite comp…