Inflatable Tech Takes Aim at Orbital Debris

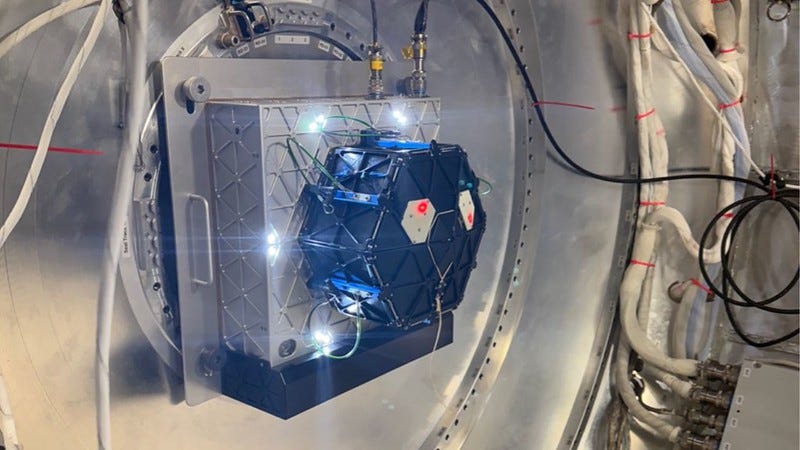

TransAstra Capture Bag System to be Tested on ISS

In space, orbital debris travels faster than a speeding bullet. To make the orbit around Earth safer for astronauts, satellites, and spacecraft, aerospace startup TransAstra Corporation developed an innovative debris removal technology. The Capture Bag system can trap objects of different shapes and sizes and even those that are tumbling, a common chall…