How to Make Roads on the Moon

ESA Project Tests the Creation of Roadworthy Surfaces

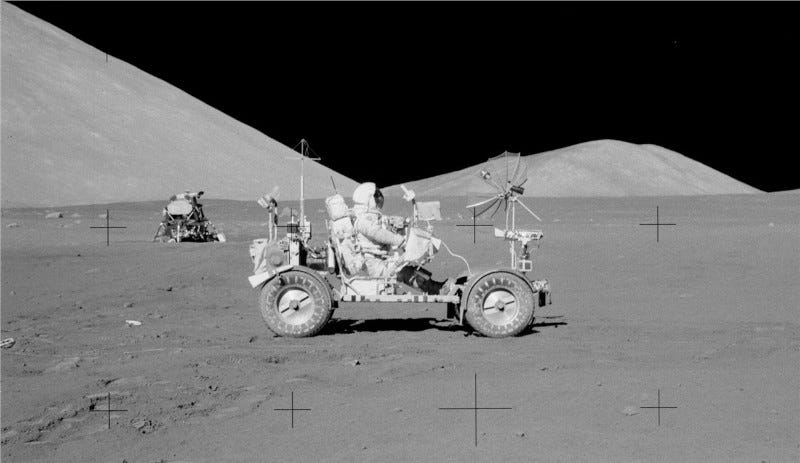

When astronauts return to the lunar surface they are probably going to be doing more driving than walking – but to keep billowing moondust at bay they are going to need roads. An ESA project reported in a recent edition of Nature Scientific Reports tested the creation of roadworthy surfaces by melting simulated moondust with a powerfu…