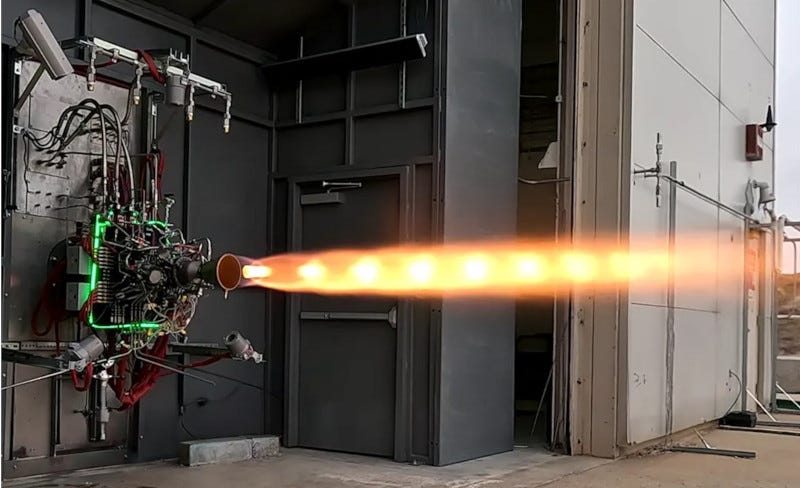

Draper Engine Successfully Hotfired in Colorado

Development Campaign will be "Aggressively" Pursued

The Draper engine being developed by Ursa Major was successfully hotfired at the company’s headquarters in Berthoud, Colorado in March, which the company calls a huge milestone for the liquid engine. The development of Draper was announced in May 2023, and with an ambitious goal of hotfiring Draper within 12 months, the engine is well ahead of schedule,…