Contract Awarded to Deliver Thruster Pointing Mechanisms for HummingSat Satellites

SWISSto12 Awards Major Contract to Beyond Gravity

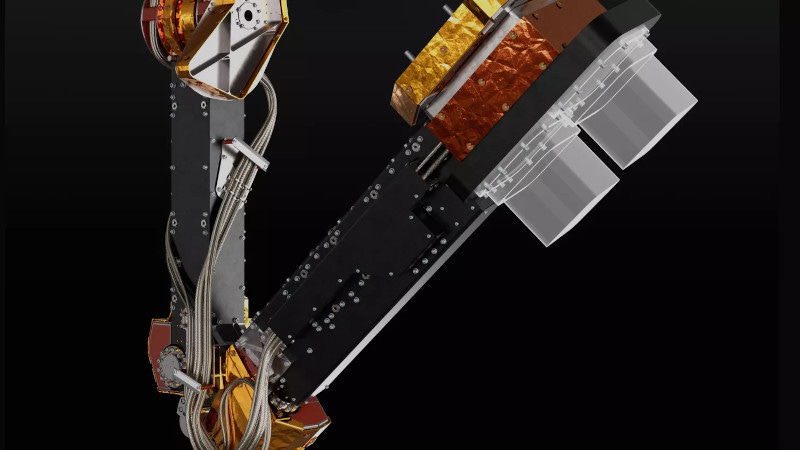

Electric propulsion pointing mechanisms for five SWISSto12 HummingSat satellites will be developed and delivered by Beyond Gravity. The small geostationary HummingSat telecommunications satellites will use Beyond Gravity’s pointing mechanisms in the form of a multi-axis robotic arm to control the satellites’ electric thrusters t…