Beyond Gravity Supplies Components for Two Launch Vehicles

Ariane 64, ULA Vulcan Employ Company’s Payload Fairings, Other Technologies

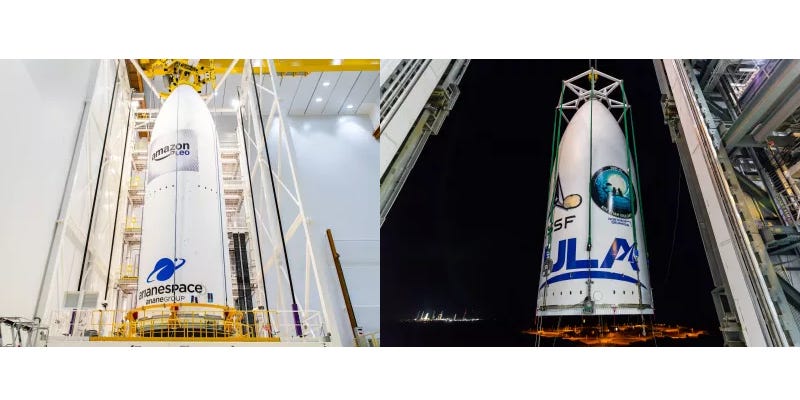

Two rocket launches last week were supported by space structure and technology supplier Beyond Gravity. Both a ULA Vulcan rocket launching a mission for the U.S. Space Force, and an Ariane 64, which launched a batch of Amazon Leo satellites on Thursday, included components manufactured by Beyond Gravity.

“The second operational Vulcan mission is an important milestone – both for the program and for our collaboration with ULA.”

Justin Elliott, Beyond Gravity

The Arianespace VA267 mission was the first for the four-booster configuration of the Ariane 6. It placed 32 Amazon Leo satellites in orbit following liftoff from Europe’s Spaceport in French Guiana. The launch vehicle incorporated several key systems for this flight: from the payload fairing, and high-precision dispenser system from Switzerland to thermal protection solutions from Austria.

“The first flight of Ariane 64 is an important milestone for Beyond Gravity and for European spaceflight as a whole,” said Oliver Grassmann, Chief Operating Officer at Beyond Gravity. “It exemplifies our close collaboration with ArianeGroup and Amazon, as well as our contribution to the next generation of European launch systems. With this planned launch, Europe is underscoring its ambitions to build modern satellite infrastructures, and Beyond Gravity is reinforcing its role as a key supplier for complex space missions.”

Beyond Gravity supplies two versions of the payload fairing for Ariane 6. Depending on the mission, the 14-meter short version is used for Ariane 62, or the larger 20-meter-long version for Ariane 64. This was the first flight for the longer payload fairing.

Earlier on Thursday, a launch from the Kennedy Space Center involving a ULA Vulcan rocket also was supported by Beyond Gravity. This was the second flight for a Vulcan booster. The payload was a Geosynchronous Space Situational Awareness Program (GSSAP) spacecraft, which will be deployed in geostationary orbit to monitor and analyze objects in space, thereby fulfilling space security tasks. The mission demonstrates the operational use of the new launch system under real-world conditions and underscores the role of the components supplied by Beyond Gravity.

Those components included the payload fairing, load-bearing structures between the rocket stages, interfaces to the payload, and systems for heat protection and separation in flight. These components are used in almost all phases of the mission – from launch and ascent to the precise deployment of the satellites – and make a significant contribution to the safety, reliability, and performance of the new launch system.

“The second operational Vulcan mission is an important milestone – both for the program and for our collaboration with ULA,” said Justin Elliott, Vice President Launchers Structures US. “This launch demonstrates how important precisely engineered structures and reliable partnerships are to the success of modern space missions.”

Beyond Gravity is the sole supplier of the payload fairing for the Vulcan rocket. The Vertical Separation System ensures the safe separation of the two halves of the payload fairing during flight. This high-reliability system developed in Zurich and manufactured in Emmen uses precision pyrotechnics for a perfectly timed separation and jettison function.

The interstage adapter is manufactured by Beyond Gravity and connects the first rocket stage with the upper stage. The payload attachment fitting establishes the mechanical connection between the upper stage of the rocket and the satellites. It holds the payload securely during launch.

Another significant contribution from Beyond Gravity is the heat shield in the rocket’s engine section. The heat shield protects sensitive systems from extreme temperatures during launch and ascent. It is designed to withstand high thermal and mechanical stress and contributes significantly to the operational safety of the Vulcan rocket.