Atomic Oxygen Tolerance Material Incorporated in D-Sail Membrane

Enhances Environmental Durability of Deorbit Device

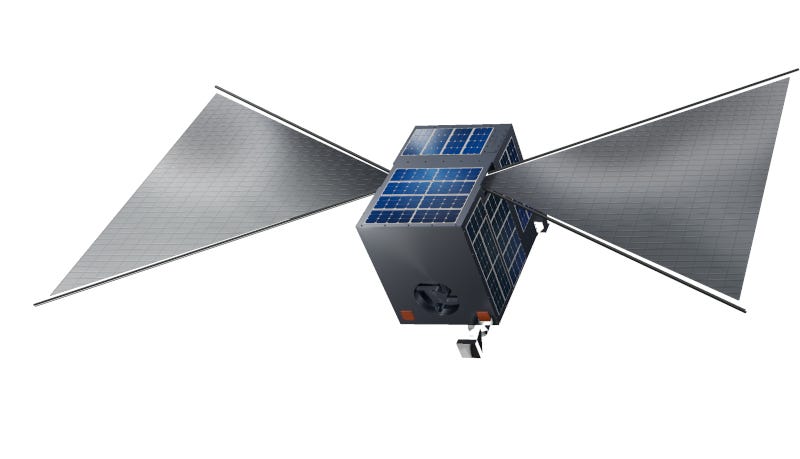

The Atomic-Oxygen (AO) Tolerant Polyimide Film “BSF-30,” developed by Nippon Steel Chemical & Material has been selected for use on the Deployable Deorbit Mechanism D-SAIL, a deorbiting device for satellites. D-SAIL, co-developed by Axelspace and Sakase•Adtech, will be installed on all seven of Axelspace’s next-generation Earth observation microsatellites, GRUS-3, scheduled for launch in 2026.

There are currently thousands, possibly tens of thousands of satellites in Low Earth Orbit (LEO), and the accumulation of space debris has become a serious concern. Axelspace has established the “Green Spacecraft Standard,” a guideline for fostering sustainability in satellite development and operation and has jointly developed D-SAIL with Sakase•Adtech to facilitate swift removal of satellites from orbit after their operational life ends, helping to protect the orbital environment. Sakase•Adtech is responsible for the design and manufacturing of the membrane deployment mechanical system for D-SAIL, while Axelspace mainly handles the electrical design and overall product functional design.

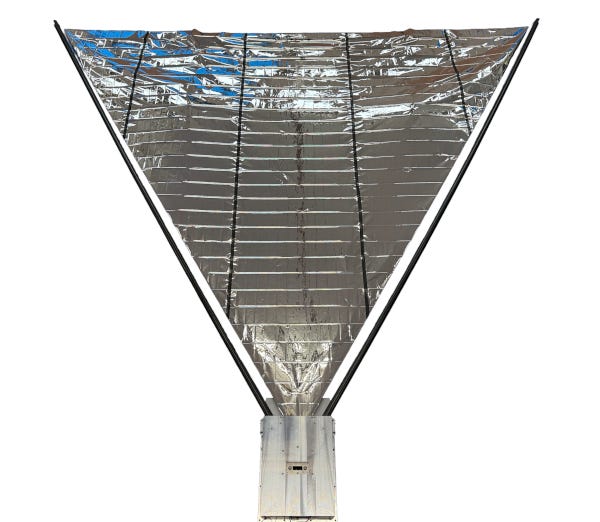

Incorporating the AO Tolerant Polyimide Film “BSF-30,” developed by Nippon Steel Chemical & Material, as the membrane material of D-SAIL, will mitigate membrane deterioration in the harsh LEO environment and improve the device’s durability and reliability in orbit.

Upon the termination of the satellite’s operation, D-SAIL deploys a membrane initially folded into a compact, fist-sized form, expanding into a surface area of approximately 2 m² which will encounter resistance of the faint atmosphere present in LEO. This will gradually reduce the satellite’s altitude, shortening the time required for the satellite to deorbit to just a few years to prevent the increase of space debris caused by collisions with other satellites or debris.

In addition, AO is produced in LEO when oxygen molecules in the atmosphere are decomposed by the Sun’s ultraviolet rays. AO causes oxidation of the satellite’s surface materials, leading to performance degradation and shortened lifespan. BSF-30 is an AO-resistant Siloxane-modified polyimide resin which forms a Silicon Dioxide (SiO₂) coating on the membrane to mitigate AO deterioration after D-SAIL’s deployment in LEO.

Through this initiative, Sakase•Adtech, Nippon Steel Chemical & Material and Axelspace will prevent the increase of space debris and contribute to improving space sustainability.